Injection molding is favored by many industries because it can satisfy various design needs as a unique manufacturing method to mass produce complex structured products. For instance, plastic products, glass fiber composites, and metal castings can all be mass-produced using the injection molding process. Metal materials, which are difficult-to-process, are usually manufactured through the lost-wax casting (or investment casting) process to meet requirements for precision and surface finish. The investment casting process is widely used when manufacturing various products, such as golf heads, artificial joints, and a variety of mechanical hardware; especially for valve products, aerospace, marine, and automotive turbine components, which have higher standards for strength and corrosion resistance. This special process can also greatly reduce the cost of secondary processes.

The investment casting process mainly consists of six steps: 1) Wax injection 2) Assembly of wax tree 3) Shell building 4) Dewaxing 5) Casting 6) Knockout. The appearance and size of wax patterns will have a direct impact on whether the shells can produce castings that meet specifications. The production efficiency of the wax patterns will directly correspond to mass production capability. There are many unsolved problems in wax pattern manufacturing, such as short shots, flow lines, sink marks, warpage, etc. This usually requires secondary processes to fix and therefore increases production time and costs.

The nature of wax is different from the plastics in the injection molding process and the metals in the casting process. With larger volumetric shrinkage, wax shrinkage is one of the most vexing problems of investment casting. Due to low thermal conductivity, wax patterns often encounter improper solidification and sink mark problems. Moldex3D has extended its simulation capabilities from the plastic injection molding process to the precision casting process to fully cater to industry needs.

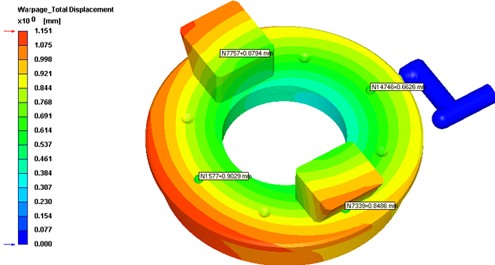

Moldex3D Investment Casting solutions (see Figure 1 and Figure 2) can not only help optimize parameter settings of wax injection precision in the casting process, reduce potential defects in the molding process, but also provide design solutions for molding. It can also accurately predictthe size of the wax pattern after shrinkage and optimize the mold size. Furthermore, the Moldex3D Material Lab also provides a full spectrum of material testing, including viscosity, volume expansion, coefficient of thermal conductivity, specific volume, heat capacity and other measurements of the properties of wax. This offers a complete investment solution for the casting process industry.

Â Â Â Â

10%Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â 40%

Â Â Â

80%                                          90%

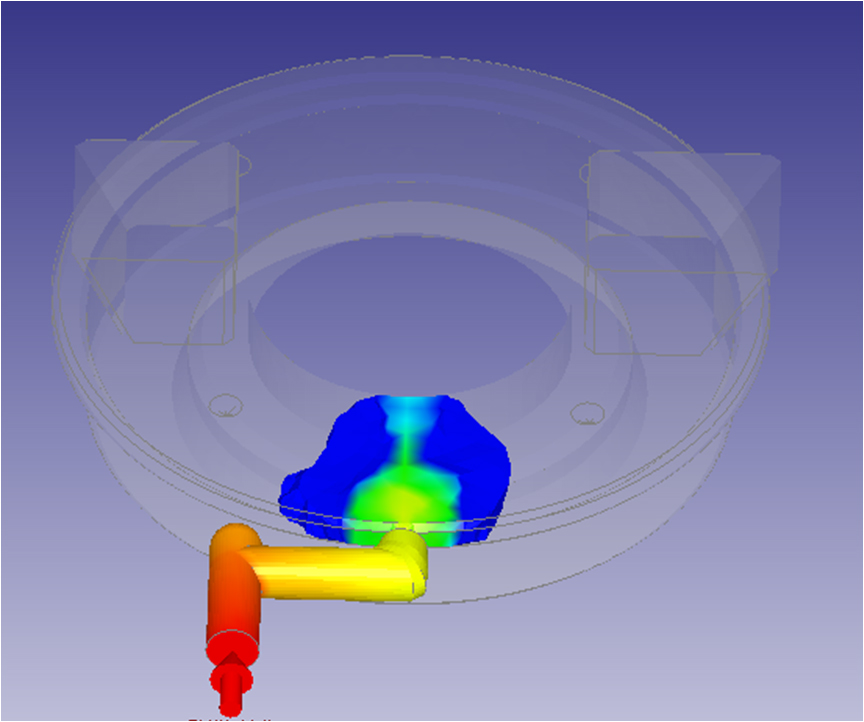

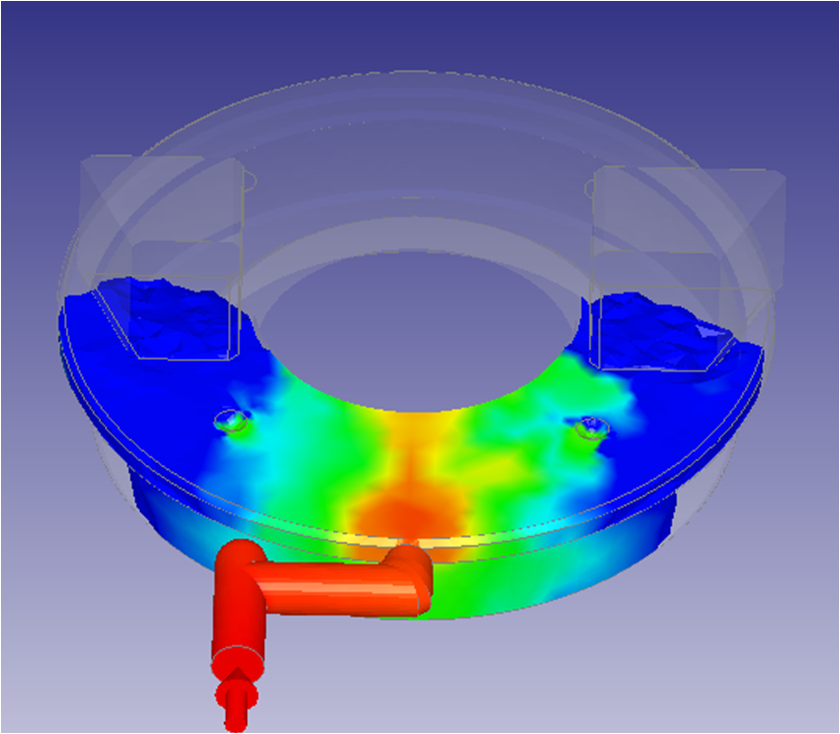

Fig. 1  Wax injection melt front progressionÂ

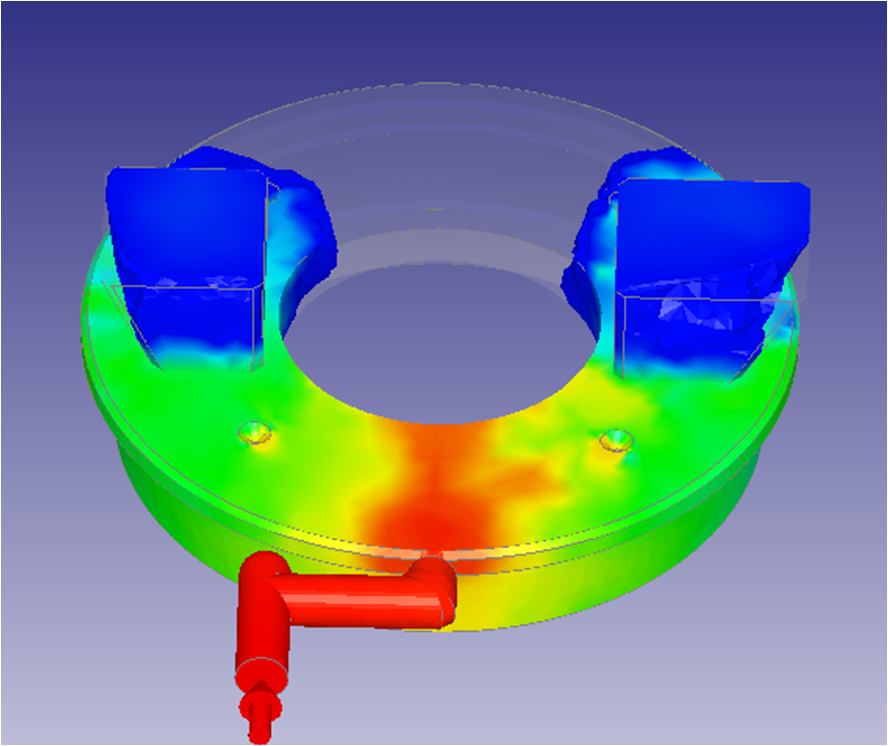

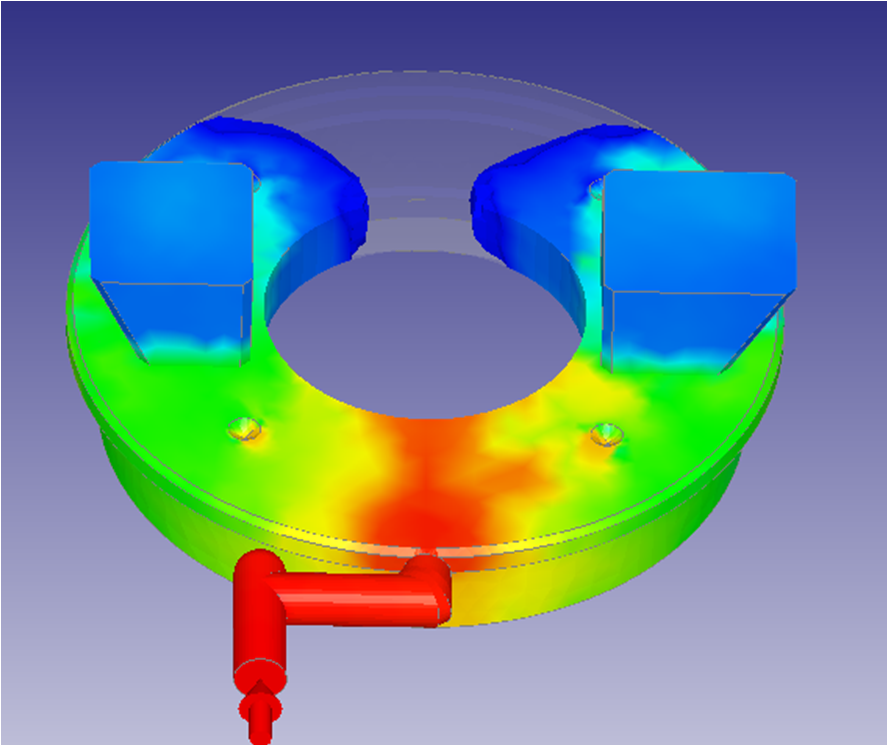

Fig. 2 Â Wax pattern displacement

The raw material for making the tray, double-sided silicone oil, is not easy to stick, good quality, high transparency

PET SHEET Double-sided silicone oil

CANGZHOU XINFENG PLASTIC CO.,LTD , https://www.xinfengplastics.com